Low-Inertia Motor (DSD Series)

S-DSD SLENDER DYNAMIC SPIN DYNAMO H-DSD HEAVY DUTY DYNAMIC SPIN DYNAMO

These motors boast super low inertia and are optimal for servo applications and automotive testing.

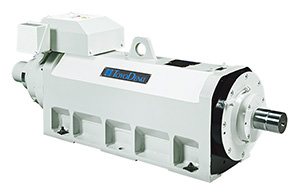

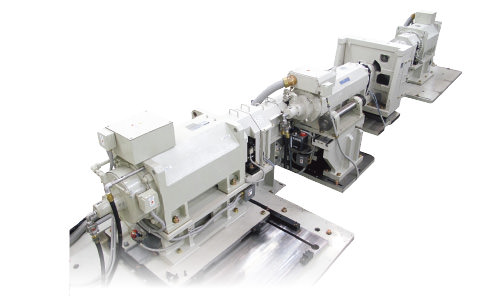

Sample configuration of dynamo equipment for automotive testing

These dynamos enable you to build test systems that shorten development schedules and improve performance in the development of next-generation automobiles. We support systems with all sorts of configurations based on our customers’ requirements. Please contact us for more information.

Features/functionality

Lowest inertia in the industry

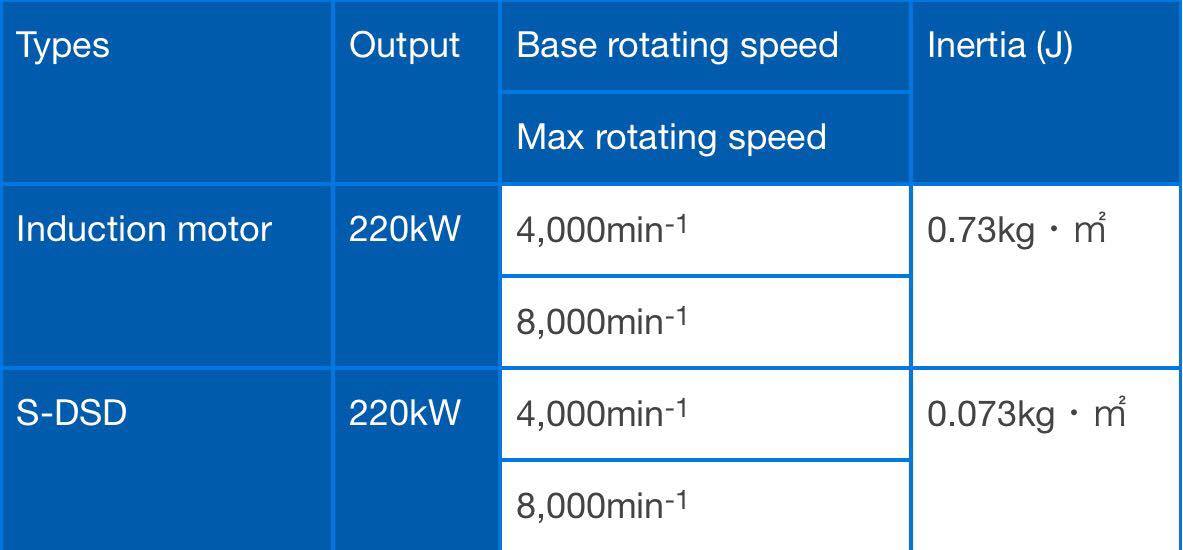

To reproduce the responsiveness of an engine, we pursued low inertia even further based on a low-inertia permanent magnet sync motor (ED motor). The inertia moment (J) of our S-DSD series motors is one-tenth that of other motors with the same output.

Comparison of inertia values between an induction motor and S-DSD

Transient operation on the level of a real vehicle

Combining a low-inertia S-DSD series dynamo with a VF66C high-response inverter enables a torque frequency response of 2.4 kHz. This makes it possible to better reproduce behaviors that approach actual automobile engines. *See here for more in depth specifications.

VF66C high-response inverter

VF66C high-response inverter

Capable of being attached under the same conditions as an actual vehicle

Size and weight have been dramatically reduced compared to ordinary ED and UF motors. Configurations that approximate an actual vehicle, which has been impossible in the past, such as FF transaxel testers, are now possible. And when combined with a drive mechanism that moves up, down, and side to side, tests under the same conditions as an actual vehicle are now possible.

FF transmission bench

FF transmission bench

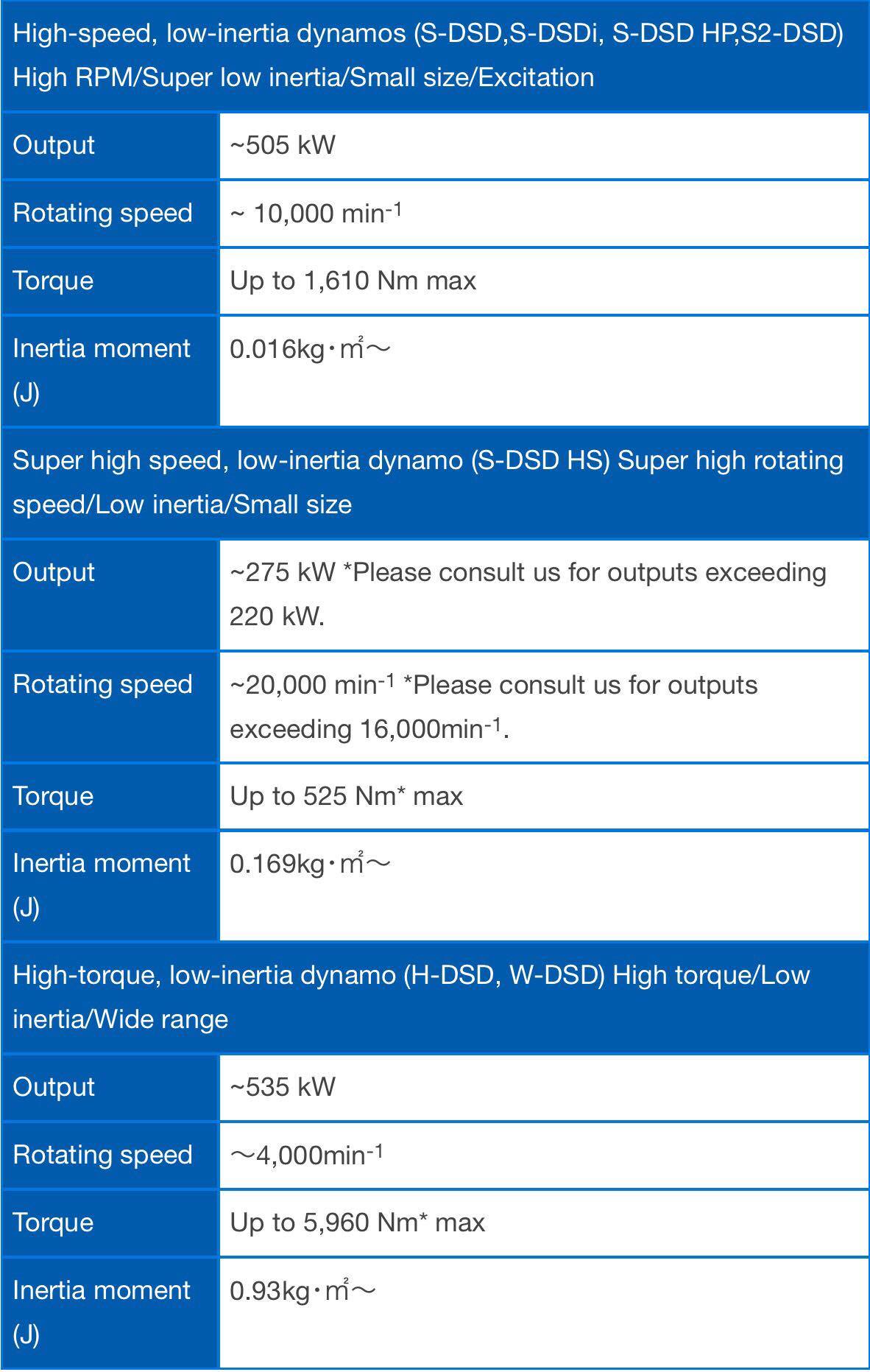

Specifications